DEHydS - Pump / Motor

After testing our linear engine it became apparent that a new hydraulic pump/motor design was required if this engine was to ever be used to propel cars and trucks. After reviewing many patents and current production motor designs the choice was made to use a radial piston arrangement pushing against a cam ring. We will vary the displacement, speed and torque with digital valves controlled by a microprocessor, pressure transducer, and encoder feedback.

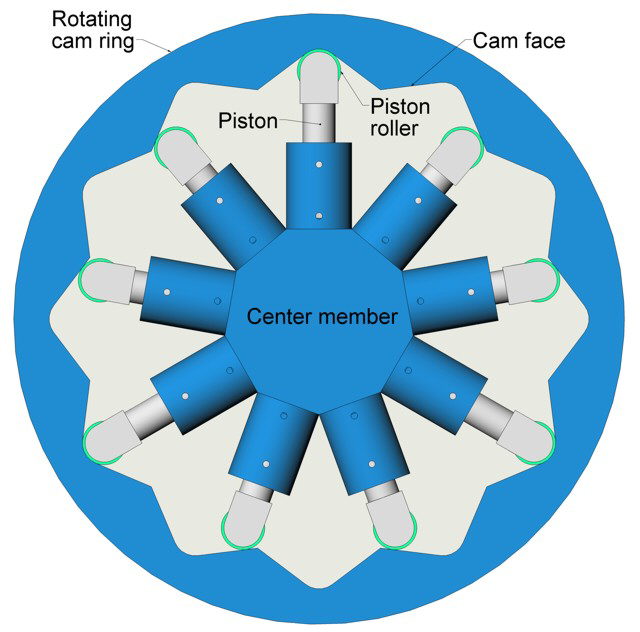

The drawing below shows our basic design intent. The pistons with rollers on the end slide in bores that are part of a center member that is stationary. By extending the pistons against the cam faces in a sequence torque is generated for acceleration and rotational speed can be maintained. For regenerative braking a pilot pressure extends the pistons against the cam faces. As the cam rotates into the piston roller it forces the pilot pressure back into accumulator storage to be reused for storage. Advantages of this design are low inertia, the ability to have high torque at low speed, a very high power to weight ratio, and high mechanical and fluid power efficiencies when operating at low power levels.